From the idea to your product

DESMA Mouldmaking offers innovative product development.

In close cooperation with the wishes of our customers products are supported throughout the development phase until they are ready to go into production.

We have been inspired by the wishes of all our DESMA customers. They in turn value a partner who brings a vast amount of experience into all phases of product development for fast, successful market entry of their products. At DESMA Mouldmaking our 25 highly motivated employees have made this a priority.

DESMA Mouldmaking adjusts its services according to the individual needs of our customers. The spectrum of services ranges from the concept creation of both upper and sole design through various modelling processes further to design assessment and up to and including the manufacture of collection prototypes. Thus the mouldshop is able to take advantage of the knowledge and expertise of the experts and businesses with whom DESMA is in partnership.

Designed by DESMA

- Highly-skilled AND creative DESIGN team

- Close cooperation with customers

- supported by state-of-the-art technology

- IN-HOUSE SAMPLE PRODUCTION

TRANSFERRING the customers’ plans into market success

THE BEGINNING OF THE ARTWORK

VISUALIZATION OF THE CUSTOMER'S IDEA

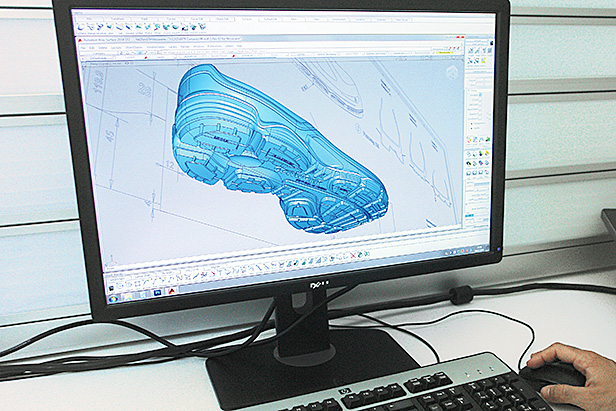

3D SURFACE MODELLING

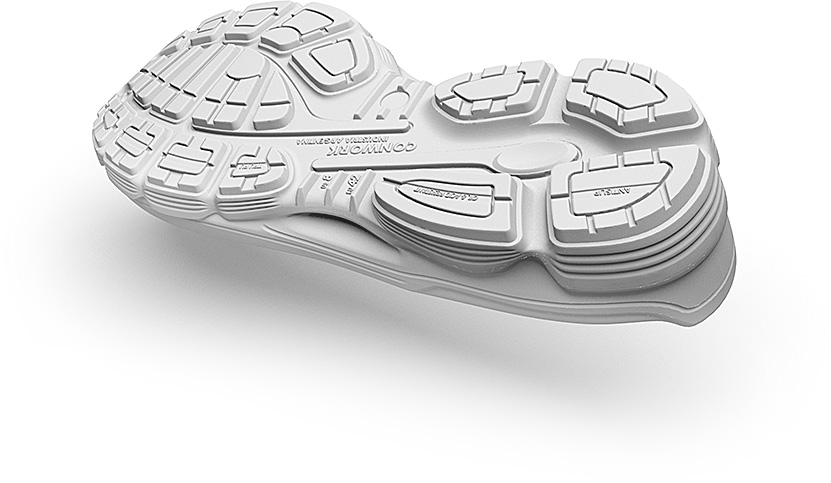

3D PRINT RAPID PROTOTYPE SOLE

LASER ENGRAVING

DIRECT SOLING MOULDS

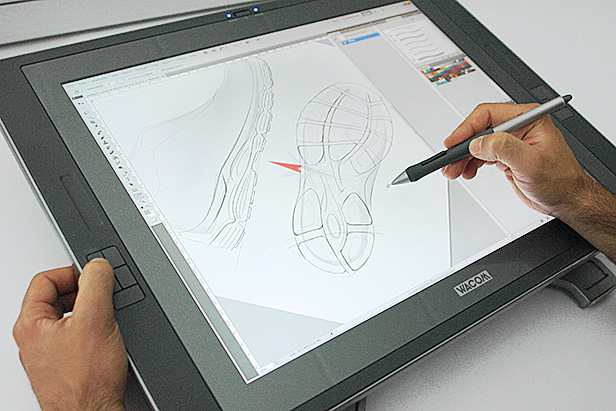

In cooperation with our customers our designer first creates an exact description of the product. Both functional and emotional aspects are considered in addition to brand identity. In the next phase a computer-generated transformation of the product description is made in the shape of photo-realistic upper and sole designs as well as an appropriate last.

An early process oriented upper quality assessment can, if required, allow enough time for the process to be optimised. In the modelling phase the designer creates a three-dimensional composition of the sole under consideration of prevailing production conditions such as upper structuring and the injection technique.

The result is a 3D simulation of the sole which allows the customers to precisely assess the design details and which can be professionally prepared for presentations. From the 3D sole data both hard and flexible model soles can be created, fitting may be tested. Customers have the opportunity to make vital production decisions during an early stage in the product’s development process.

LET US SHOW HOW WE CAN TURN YOUR IDEAS INTO REALITY. ![]()