automated material supply with integrated robots

AUTOMATION – FIT FOR THE FUTURE

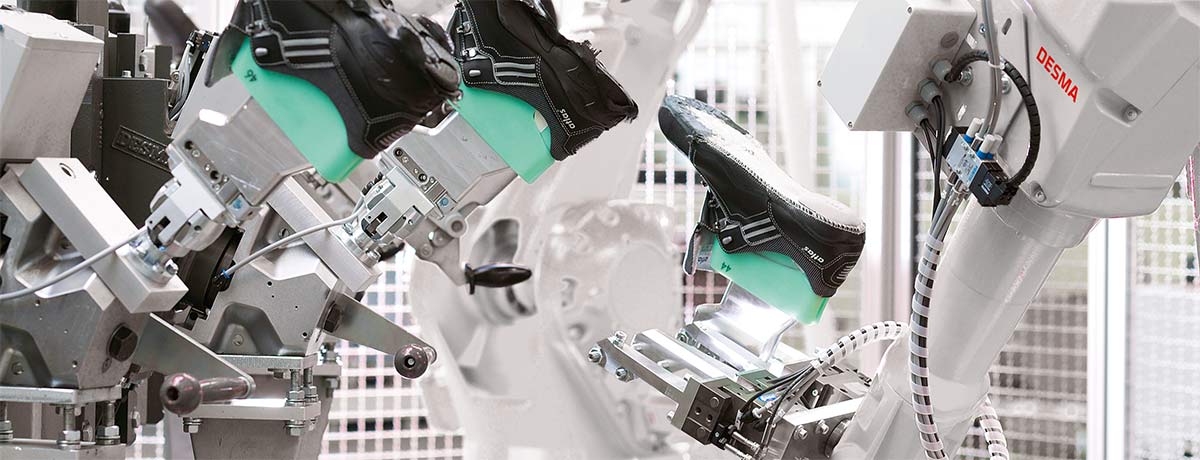

At the centre is the person, whose capabilities are expanded by DESMA automation. This includes a network of individual production units connected via interfaces as well as the compilation and management of large data sets. The production of shoes occurs via automated material guiding and integrated robots.

amir® HIGHLIGHTS

- REDUCTION IN OPERATING COSTS

- IMPROVEMENTS IN PRODUCT QUALITY

- BETTER WORKING CONDITIONS

- INCREASE IN PRODUCTION PERFORMANCE

- INCREASE IN MANUFACTURING STABILITY

- REDUCED MATERIAL INPUT

The seventh DESMA machine:

36 stations, A High degree of automation

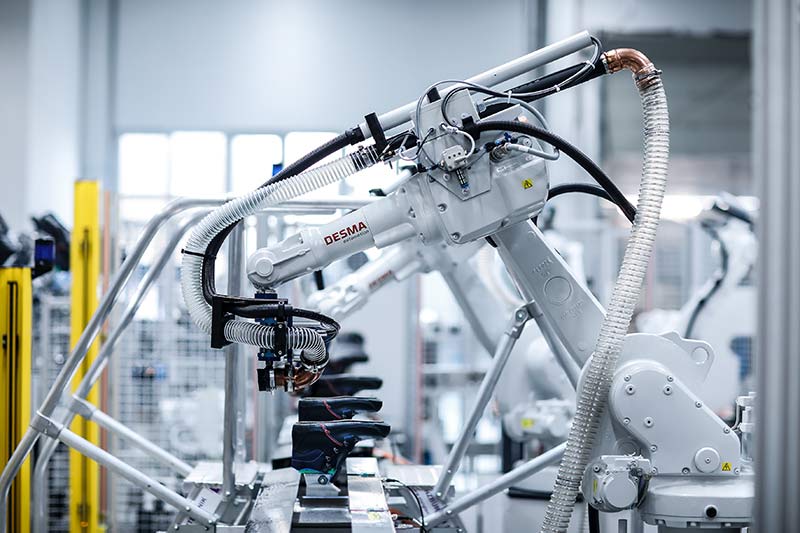

With 36 stations, a highly-automated amir production line and a total of seven robots, the new DESMA rotary table is currently the largest and most modern direct soling machine offered by DESMA.

It is the seventh machine that DESMA has delivered to ATLAS, its partner for many years, a clear sign of the trust that has grown steadily over the 40 years in which these two successful business enterprises have worked together.

On purchasing this latest machine, ATLAS has entered a new dimension. “The new machine will make our traditional production methods more flexible; the individual work stages are more precise and the production process as a whole more efficient,” explains Dieter Bade, DESMA Sales Manager.

Robots perform individual steps such as roughening the upper, placing steel soles, applying release agent, trimming sole edges and picking and placing, i.e. automated parts supply from the amir system to and from the rotary table. This eases the workload of the employees, who no longer have to perform these laborious and often monotonous tasks.